VERSIFOAM® LATEST NEWS

Your heating, ventilation, and air conditioning system keeps your home or office comfortable. It’s also creates openings through which drafts can enter the interior space and reduce your comfort level. Sealing those openings with spray foam insulation will prevent air from seeping in and out of your building and save money in the long run.

In our energy conscious world, much has been written about R values and net zero energy buildings. People differ on the methods and timeline for achieving environmental sustainability. However, most of us understand that reducing carbon gasses from fossil fuels needs to be a priority. One important step in this direction is ensuring that your home or commercial building has a tight building envelope.

What is the building envelope?

According to Wikipedia, the building envelope “is all of the elements of the outer shell that maintain a dry, heated, or cooled indoor environment and facilitate its climate control.” It is the system of components that protects against movement of air, moisture and heat. Or to put it another way, the physical construction that separates the conditioned areas inside a building from the unconditioned areas outside of the building. Contractors and builders pay attention to the building envelope during construction when they work to eliminate openings in the foundation, walls, and roof.

Why is it important?

The air barrier system within a building envelope is a critically important element for economic control of moisture, temperature regulation, and for preserving structural integrity. An inadequate barrier system will allow leakage of air through holes, cracks, and gaps. The end result is movement of air, moisture and heat between the conditioned and unconditioned environments. An inadequate barrier system will allow heat to flow through the home and between its surroundings by conduction, convection and radiation. Simply stated, heat will always flow from hot to cold resulting in increased energy costs wherever an inadequate barrier system is present.

When this occurs, rain, groundwater, and moisture vapor cause deterioration in the building’s structure. Uncontrolled air flow makes it too cold in the winter and too hot in the summer. We become uncomfortable in our own homes. If you regularly describe your home as “too drafty”, your building envelope is probably not “tight” enough. A tight building envelope provides numerous benefits including a higher level of personal comfort, energy savings, cost savings, pest control, and fewer expensive repairs from moisture damage. The more airtight the building, the less energy it will use and the lower the cost will be for the property owners or their tenants.

What role does spray foam insulation play?

Spray foam insulation contributes to a better performing building envelope by completely sealing any gaps and crevices. This prevents air infiltration, moisture infiltration, and the intrusion of dirt and pollutants from the outdoors. The air barrier system of spray foam insulation is a critically important element for economic control of heat transfer. An inadequate barrier system will allow leakage of air through holes, leaks, cracks and gaps. This allows heat to flow through the structure and between its surroundings. VersiFoam provides an excellent barrier system that saves both money and energy.

5 reasons to use spray foam insulation in your building envelope:

- The application is quick, clean, and easy — especially if you choose VersiFoam with its patented U-Control dispenser

- It provides a better, longer lasting seal than other sealing products.

- It’s good for the environment. The energy loss from air leakage can be as much 40% in the average home. Spray foam insulation saves energy and reduces the use of fossil fuels, thereby helping to reduce global warming gasses.

- It absorbs noise from the outside and inhibits the transfer of sound between rooms.

- It’s the insulator of choice for house flippers such as The Property Brothers and Joanna Gaines.

Use VersiFoam spray foam insulation to seal and insulate around those leaky windows, doors, attics and other areas in your home. Your home or place of business will be healthier and last longer. And you will feel better and spend less money.

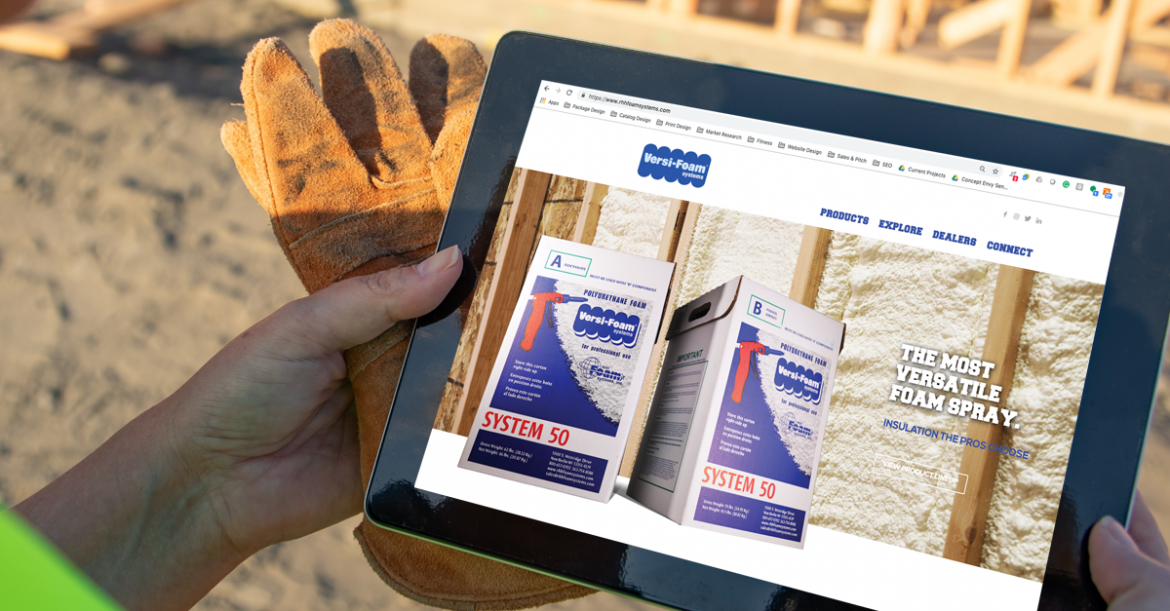

Today we are very pleased and excited to announce the recent launch of our brand new VersiFoam website. The new site highlights each product in the VersiFoam line and makes product information easier to find and understand.

Richard Heitzer founded VersiFoam in 1981 after he developed the patented U-Control dispenser. The dispenser allows you to regulate the quantity and rate of spray foam insulation being dispensed. Today VersiFoam is used in dozens of applications including residential and commercial construction, marine flotation, movie props, cold storage, and vehicle insulation.

Here are few things to check out on the new website:

- The “Spray It, Don’t Pay It” Foam Insulation Calculator. Use this tool to accurately estimate the amount of spray foam you will need for your project. First, enter values for foam density, foam thickness, and square footage. Then click the “calculate” button to see how many VersiFoam spray kits you need to complete your job.

- Our “Pull The Trigger Now” Dealer Locator. Use our interactive map to find the VersiFoam dealer closest to you, or search by state or county.

- “Check Out The Tech Specs” is a new page that combines all our technical specification literature in one convenient location. For some products we have safety sheets available in both English and Spanish.

- The VersiFoam Video Collection. Here you can find how-to, trouble-shooting, and safety videos, as well as a VersiFoam product overview.

We invite you to explore the entire VersiFoam website. We believe you will find it easier to navigate, easier to understand, and easier to find exactly what you’re looking for.

Among spray foam insulation products, VersiFoam is the easiest to use, the fastest to apply, the most portable solution, and it saves money. You don’t need an outside source of pressure or power. In addition, the patented dispensing gun is able to seal awkward spaces quickly and easily. These features reduce the amount of time it takes to complete an insulation job.

Every business that wants to stay in business must make a profit. Once you’ve been awarded a job, it’s important to complete the work cost effectively so that you can earn a profit. Accordingly, VersiFoam helps you by reducing the cost of labor and the cost of unproductive downtime with our simple 5-step application process.

To apply VersiFoam spray:

- Step 1: Turn the tank valves to the on position.

- Step 2: Click one of the nozzles into place on the dispensing gun.

- Step 3: Disengage the safety.

- Step 4: Point the dispensing gun at your spray foam target.

- Step 5: Pull back on the handle and dispense the foam insulation.

Whether you’re working on a large construction build or a smaller home project, applying VersiFoam is just as easy as that.

VersiFoam spray foam insulation kits are the most dependable solution for money-saving residential and commercial insulation projects. Labor is the highest cost of any project. Using VersiFoam spray insulation will increase the productivity of your workers and your bottom line.

The United States Department of Transportation has a new shipping classification for the VersiFoam low-pressure spray polyurethane foam systems. The prior product description fell under: UN1956 Compressed Gas, N.O.S. (Fluorinated Hydrocarbon, Nitrogen). The new product classification for shipping by all modes of transportation (road, air, and vessel) will be as follows: UN3500 Chemical Under Pressure, N.O.S. (Fluorinated Hydrocarbon, Nitrogen).

It’s that time of year again – when cooler temperatures can affect the performance of your VersiFoam® System. To ensure the peak performance of your VersiFoam® System and quality foam production, here are a few helpful tips:

Never store VersiFoam® products in temperatures lower than 40°F (5°C). Storing at these temperatures may cause the chemicals to freeze. If the “A” component freezes, it will crystallize, creating blockages in the dispenser. Once this occurs, it cannot be fixed.

Always warm the chemicals to a temperature between 65°F to 90°F(18°C to 32°C) before using. Refer to the temperature sensing strip to be sure it is well within the green zone. During application, continue to monitor the temperature strip. If it begins to move toward the blue zone, warm the chemicals again. Cooler chemicals will result in foam that is “A” rich, which will be darker in color and have a crunchy surface.

Bring your VersiFoam kits into a warm/conditioned space for at least 24 hours prior to using. After warming the chemicals, be sure to shake the tanks well to ensure a uniform temperature throughout.

Always warm the surface onto which you are applying the foam to a temperature between 65°F to 90°F (18°C to 32°C). Colder surface temperatures may result in adhesion problems and reduced yields. For answers to more questions, visit our support page.