Most people don’t realize how complex and fragile a cold supply chain is. Cold chain management is an intricate process that ensures that temperature-controlled products, such as pharmaceuticals and food, remain at their prescribed temperature range from start to finish. Cold storage insulation is a critical component in the design of the cold storage supply chain.

Great effort is expended to ensure that the cold chain remains unbroken from start to finish. Before and after transport, perishable products are stored in facilities where the optimal temperature can be tightly controlled and carefully monitored. These buildings are the first and last links in the cold supply chain.

“Temperature-sensitive products—everything from meat and fish to certain chemicals and pharmaceuticals—require controlled environments from the moment they’re manufactured until the moment they’re used or sold.”

Cold Storage Insulation

Most cold storage facilities are constructed using pre-insulated sandwich panels. Sandwich panels are modular, heat resistant, and provide an excellent air barrier. However, at transitions between the panels or unsealed openings, warm, moist air can infiltrate. Avoiding these types of thermal leaks is imperative in cold storage design so that the facility has a tight building envelope and continuous vapor barrier.

Continuous thermal insulation maintains cold temperatures by preventing the travel of heat between spaces through the invisible process of air exchange. If cold air is allowed to leak outside of the cold storage facility, an equal amount of hot, humid air will enter to replace the cold air that was lost. The space needs to be completely enclosed so that it can be held at the required temperature 24 hours a day, seven days a week, and 365 days a year.

Once the sandwich panels are installed, any gaps that allow the exchange of hot and cold air must be sealed completely. In “The do’s and don’ts of cold storage”, author Jennifer Carr encourages contractors to pay close attention to every little opening and penetration. “As you’re making the various transitions, it’s often hard to find board insulation that gets into all the “nooks and crannies.” That’s why it’s important to use foam-in-place insulation at transitions between the wall and roof to maintain a continuous thermal envelope.”

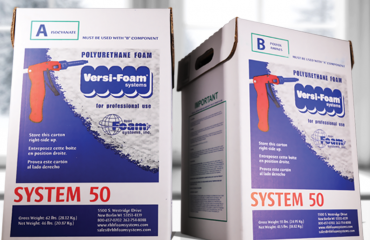

VersiFoam® For Cold Storage

Foam-in-place insulation is a spray polyurethane foam like VersiFoam®. It’s used to seal the juncture where the roof meets the wall, wall and ceiling junctures on the interior, floor to wall junctions, and in corners. It expands to fill the entire space where it’s applied, sealing cracks and crevices completely. The closed cell formula protects against the incursion of heat and moisture proving the tight envelope and vapor barrier that’s required in a cold storage facility.

VersiFoam® spray foam insulation kits offer the following advantages for cold storage insulation:

- Exceptional thermal performance.

- Advanced dispensing capabilities provided by our patented U-Control gun.

- Portable, with no outside power or pressure source needed.

- Superior adhesion to metal and other building materials.

Cold supply chains are an indispensable part of modern life. The ability to maintain low enough temperatures to preserve food and medicine for long periods of time has had a positive impact socially and economically compared to a century ago. VersiFoam® is proud to play a small part in the cold storage supply chain by providing thermal insulation for low temperature warehouses.